MSizer Family

The MSizer Family offers powerful and versatile screening machines based on the MOGENSEN Sizer® principle. Thanks to an innovative screen deck concept with optimized screen inclination, screening quality is enhanced, and throughput is increased. The different models are tailored to various needs: the MSizer Compact is ideal for companies with limited space, delivering high screening performance in a compact design. The MSizer Extend provides a flexible solution for medium to large plants, excelling in process stability and efficiency. For large-scale industrial applications, the MSizer Giant is the ultimate choice, designed to process massive material volumes efficiently. With fast screen change technology, high reliability, and maximum productivity, the MSizer Family is the perfect solution for businesses looking to optimize and expand their production processes.

functionality

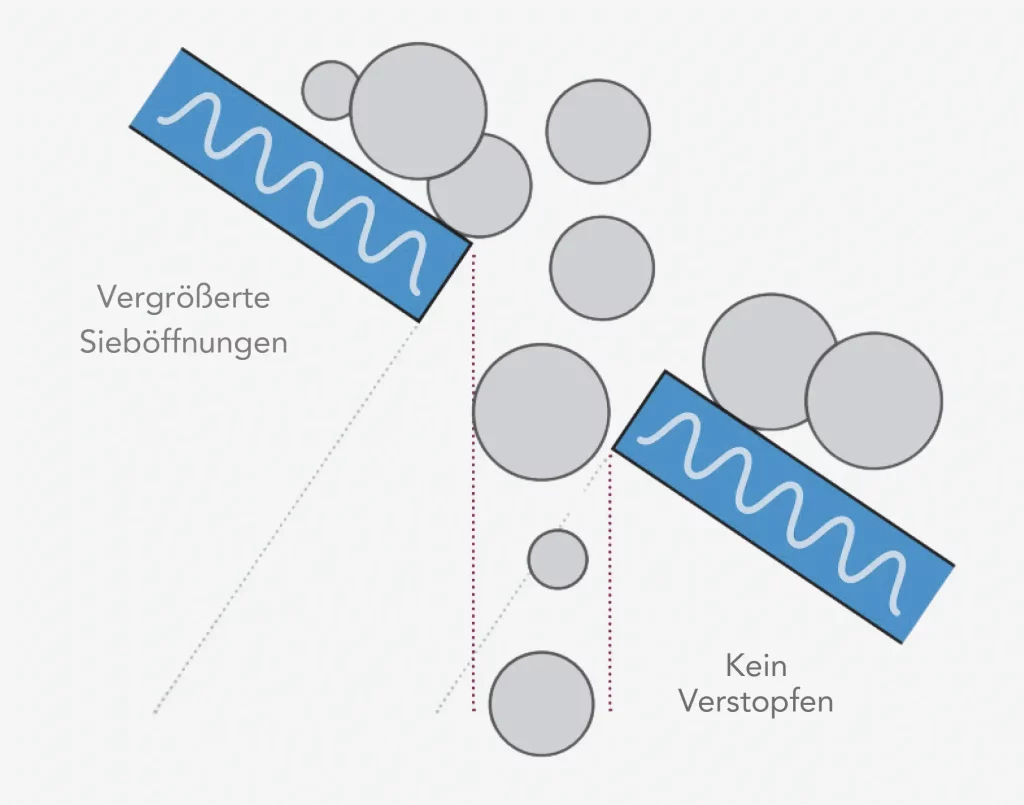

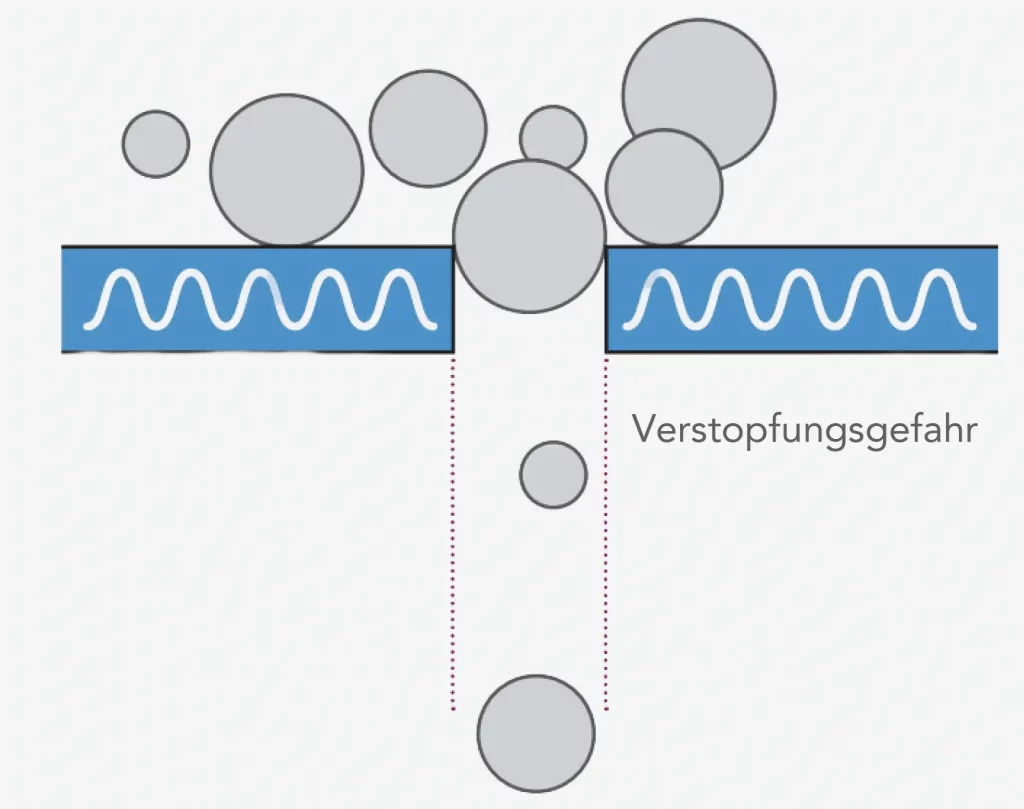

The MSizer Family is the most powerful and versatile screening machine based on the Sizer principle. The machine combines economic and operational efficiency by utilizing a new screen deck concept with a modified screen inclination angle. The MSizer’s one to six screen decks significantly reduce screen change times thanks to the quick screen-change mechanism. The screen decks of the MSizer Extend operate in a linear vibration pattern, while the newly developed MSizer Compact features an elliptical screen deck movement. With precisely adjusted vibrations and elliptical motion, fine particles in the feed material flow quickly and almost vertically downward, while coarse particles are efficiently screened out of the material stream. Clogging is effectively eliminated, resulting in a significantly increased throughput. Unlike conventional flat screens, the mesh openings of the MSizer are larger due to the optimized screen inclination, promoting superior screening quality. The larger mesh openings, compared to the cross cut, prevent material layer formation and clogging, leading to significantly higher throughput and longer screen deck life.

MSizer Compact – Maximum Performance in Minimal Space

The MSizer Compact is the ideal choice for companies operating in confined spaces while still requiring high screening performance. This machine combines efficiency and precision in a compact design, making it perfect for smaller production facilities without compromising performance.

MSizer Extend – Versatility for Medium to Large Plants

With the MSizer Extend, MOGENSEN offers a flexible solution for businesses that value adaptability and efficiency. This machine is optimal for medium to large applications, delivering impressive throughput alongside high process stability.

MSizer Giant – Ultimate Performance for Large-Scale Industrial Applications

The MSizer Giant is the flagship of the MSizer Family, designed specifically for large industrial applications. This machine is built to efficiently process massive material volumes, offering the ultimate solution for industries with the highest productivity demands.

Each machine in the MSizer Family is developed with the same commitment to quality, efficiency, and reliability, ensuring that there is a suitable MSizer for operations of any size. Whether you want to expand your production capacity or optimize your current processes, the MSizer Family offers the perfect screening solution to drive your success.

product details

Our MSizer offers a variety of innovative features and configurations specifically designed for use in demanding industrial environments. With its ATEX-compliant design, it ensures safe operation in environments prone to explosions.

The MSizer is available in a standard or stainless-steel design, offering the highest quality and durability. The integrated motor and brake control, as well as electronic machine monitoring, guarantee efficient and safe operation. Additionally, the integrated material distribution ensures consistent processing, while mechanical and pneumatic screen cleaning systems maintain optimal screening performance over time.

To ensure maximum operational safety, the MSizer features screen tension monitoring and electric heating of the screen decks. Additional wear protection extends the machine’s service life. The included transport and installation frame with isolation simplifies safe setup and operation in various environments.

These thoughtfully designed features make the MSizer the ideal choice for reliable and efficient material processing – even under extreme conditions.

options

ATEX-compliant design – For use in explosive industrial environments

Standard or stainless-steel construction

Motor and brake control

Electronic machine monitoring

Integrated material distribution

Mechanical screen cleaning

Pneumatic screen cleaning (Compact & Extend models only)

Screen tension monitoring

Electric heating of screen decks

Wear protection

Transport and installation frame with isolation

MOGENSEN Sizer® Principle

MSizer Principle Compared to Conventional Screening Technology

The MOGENSEN SIZER® Principle offers significant advantages over conventional screening methods, including faster separation, reduced wear, minimized mesh blockages, and high screening accuracy. It enables more efficient material processing with up to six screen decks for seven product fractions, requiring less space and consuming less energy. Additionally, it reduces downtime and maintenance costs through lower stress on the screen panels. Overall, the MOGENSEN SIZER® Principle is an advanced and cost-efficient solution for modern screening requirements. Efficiency, precision, and maintenance costs are critical factors in industrial screening processes that significantly impact overall productivity. The MOGENSEN SIZER® Principle provides an advanced alternative to traditional screening methods, offering a range of benefits that make it the preferred choice for modern screening demands.

Separation Time & Layer Thickness

The MOGENSEN SIZER® Principle is distinguished by its fast separation process due to a thinner material layer. This contrasts sharply with conventional screening methods, where thicker material layers lead to slower separation times. The thinner material layer in the MOGENSEN Sizer allows for faster processing, which is crucial in industries where time and throughput are critical.

Wear

A key advantage of the MSizer is its ability to reduce mechanical stress on each screen deck. The thinner material layer contributes to less wear and extends the service life of the screen panels. Conventional screening systems, on the other hand, experience higher mechanical stress due to thicker material layers, leading to more frequent maintenance and part replacements.

Mesh Blockage

Mesh blockage is a common issue in screening processes, but the MOGENSEN SIZER® mitigates this problem by using a thinner material layer and larger mesh openings relative to the separation point. This significantly reduces the risk of blockages. In contrast, conventional screens with thicker material layers are more prone to blockages, disrupting operations and reducing efficiency.

Screening Accuracy

Accuracy in screening is vital, particularly in industries where precision is required. The MSizer Principle allows for more screen decks and fewer blockages, ensuring high capacity and excellent screening accuracy. Conventional screens, which often suffer from poor screening accuracy due to thick material layers and frequent blockages, result in inefficiencies in the final product.

Downtime and Maintenance

Downtime for maintenance can be costly. The MOGENSEN Sizer’s design naturally results in less wear, which, combined with reduced blockages, minimizes maintenance requirements. Conventional screening systems, however, are more prone to wear and blockages, leading to more frequent downtime for cleaning and maintenance.

Screen Decks and Product Fractions

The MOGENSEN SIZER® can support up to 6 screen decks and deliver up to 7 product fractions, offering greater flexibility and efficiency in processing. In comparison, conventional screening systems typically support only 1-2 screen decks and 2-3 fractions, limiting their versatility and throughput.

Space Requirements and Energy Consumption

Space and energy efficiency are additional areas where the MSizer excels. Its smaller footprint, thanks to shorter decks and compact design, results in lower energy consumption. Conventional screening systems, with their longer decks and larger dimensions, require more space and consume more energy, increasing operational costs.

Wear & Service Costs

Overall, the MOGENSEN SIZER® Principle not only reduces wear on screen panels but also decreases the need for screen replacements, resulting in lower service costs over time. Conventional screens, which experience higher wear, require more frequent maintenance and screen replacements, driving up operating costs.

By addressing these critical factors, the MOGENSEN SIZER® Principle establishes itself as a superior, efficient, and cost-effective solution for industrial screening processes.

Application Areas

The MSizer family (Compact, Extend, Giant) offers versatile solutions for the precise classification of a wide range of materials in numerous industries. Whether in the processing of stone and earth, metallurgy, the food and animal feed industry or in mining – the high-performance screening machines ensure efficient separation and sorting of bulk materials. They are also used in the chemical industry, ceramics production, recycling and in wood and plastics processing. Thanks to innovative technology, the MSizer systems enable consistently high screening performance and contribute to the efficiency and sustainability of industrial processes.

Sand, Gravel, Chalk, Basalt, Limestone, Minerals

Iron Ore, Nickel Ore, Manganese Ore, Alumina, Fly Ash

Sugar, Cocoa Beans, Fish & Meat Flour, Tobacco, Salt

Animal Feed, Grains, Mineral Additives, Protective Screening

Fertilizers, Titanium Dioxide, Zinc Sulfate, Copper Sulfate

Bentonite, Silicon Carbide

Glass, Organic Waste, Plastic Granules

Wood Chips, Sawdust

Plastics, Pharmaceuticals, Biofuels, Pellets, etc.

MSizer Family

The MSizer Family by MOGENSEN delivers powerful and compact screening solutions for a wide range of industrial applications. This machine series stands out due to its versatility and low operating costs. The MSizer Compact enables high efficiency in minimal space, the MSizer Extend provides high throughput and excellent separation quality, and the MSizer Giant offers maximum throughput capacity with a large screening surface, making it the ideal choice for high-volume processes.

MSizer Compact

The MSizer Compact is the ideal solution for high-performance screening in limited spaces. As a compact short-deck sizer, it combines high efficiency with precise material processing and is specifically designed for industrial applications requiring maximum performance with minimal space requirements.

Powered by a single unbalanced drive, the MSizer Compact generates a unique elliptical motion that prevents screen clogging, loosens materials, and ensures uniform distribution across the screening surface. With throughput rates exceeding 40 tons per hour, it is particularly suited for the feed and food industries but is also successfully used in many other sectors.

Thanks to its flexible design, the MSizer Compact is available in standard and stainless-steel versions. An ATEX-certified version allows for use in explosion-prone environments. With its compact yet powerful design, the MSizer Compact is the perfect choice for companies seeking top-notch screening performance in confined spaces.

MSizer Extend

The MSizer Extend is a fully optimized evolution of a proven technology that has been in use worldwide for decades. Designed to meet the demanding requirements of various industries, it offers outstanding performance and versatility, effortlessly processing fine materials as small as 200 microns and coarse materials up to 100 millimeters.

With its advanced screen deck design, the MSizer Extend ensures maximum operational efficiency while maintaining a compact and robust structure. One of its key advantages is the reduction of operating costs by up to 20%, making it an especially economical solution.

Leveraging state-of-the-art technology and decades of experience, the MSizer Extend sets new benchmarks in bulk material screening, offering a future-proof, environmentally friendly, and efficient solution for companies seeking top-tier screening performance with minimal costs.

MSizer Giant

The MSizer Giant sets new standards in industrial screening technology, delivering an unmatched throughput increase of up to 35% compared to the MSizer Extend. With a capacity exceeding 80 tons per hour for sugar classification, it is the largest and most powerful sizer on the market, making it the ideal choice for industries with high material volumes, such as sugar production and the construction materials sector.

Specifically designed to meet the needs of large-scale production facilities, the MSizer Giant reduces the need for multiple screening machines or conventional screening systems. This not only optimizes production processes but also significantly lowers infrastructure and maintenance costs. With fewer machines required, higher productivity can be achieved, ensuring more efficient and cost-effective operations.

Whether for granulated sugar products, large volumes of construction materials, or other high-volume applications, the MSizer Giant delivers exceptional screening performance and impresses with its robust design. It is the ideal solution for companies focusing on high throughput without compromising on screening quality.

Key Advantages

The MSizer Family stands out with its ability to actively prevent the formation of material layers and trapped particles on the screen panels. This ensures consistently high screening performance while significantly extending the service life of the screen panels. The MOGENSEN Sizer® screening principle combines innovative technology with sustainable efficiency, providing a reliable, high-performance solution for demanding screening processes.

Reduced Operating Costs

Low energy consumption leads to reduced overall costs, ensuring long-term investment security.

Optimized Compact Solutions

Compact, maintenance-friendly design with a wide range of accessories to meet individual requirements.

Maximum System Availability

Low risk of clogging, durable screen panels, and robust design guarantee maximum operational reliability.

Highest Efficiency

Quick screen deck replacement and a well-thought-out fail-safe design allow for hassle-free maintenance.

Test Your Material at our Test Centre

At our MOGENSEN Testing Center, experience firsthand how our proven MSizers process your material with the highest precision and efficiency. Rely on cutting-edge technology and proven results. Contact our sales team to schedule an appointment and test your material under real-world conditions.

We look forward to supporting you!

Get in touch with us

Reach out to us quickly and directly by using the contact form. We will respond as soon as possible!