GSort R

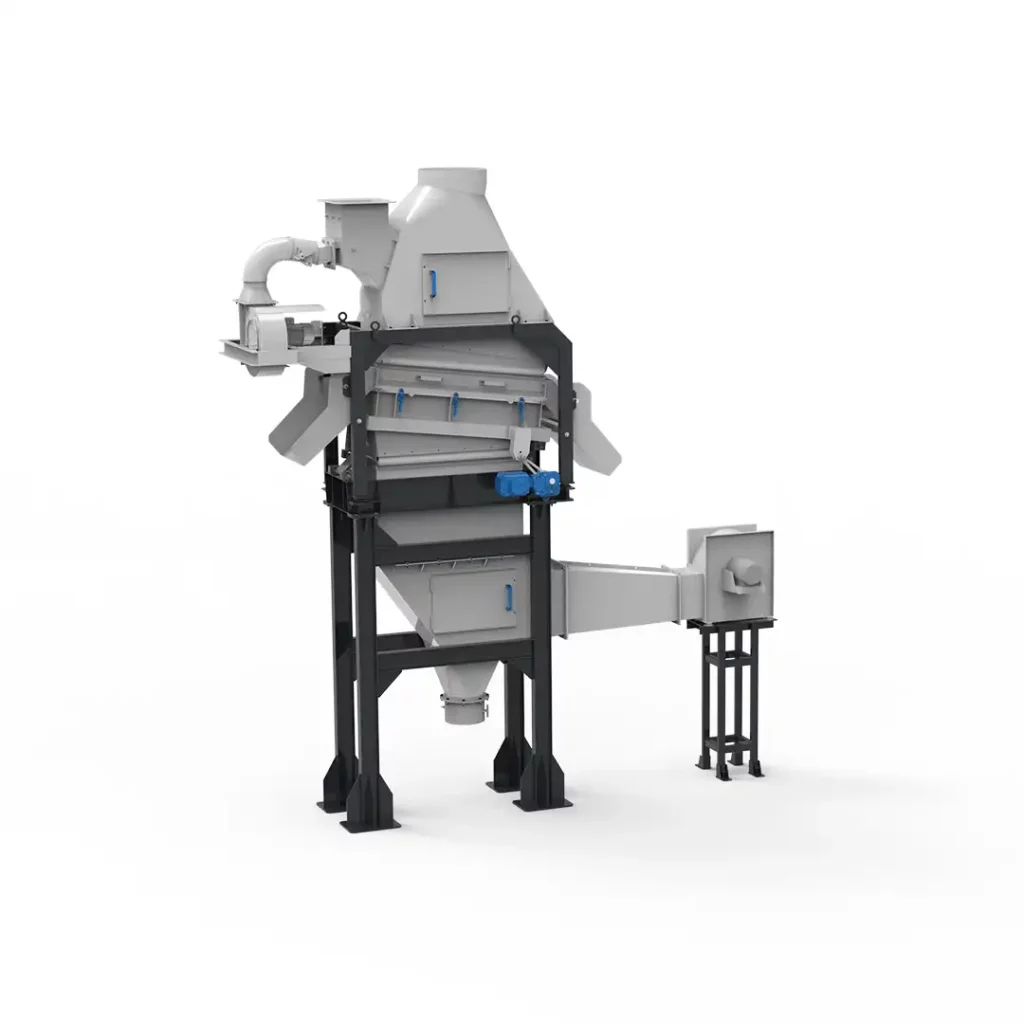

The GSort R from MOGENSEN offers a highly efficient and versatile solution for density separation in the recycling industry, specifically designed to meet the demands of modern recycling processes.

With its advanced, precision-engineered technology, the GSort R is particularly suitable for processing lightweight to medium-weight materials such as plastics, glass, textiles, and other recyclable substances. Designed for maximum flexibility and adaptability, it is ideal for circular economy applications where various materials need to be separated with high precision. The GSort R not only delivers exceptional sorting accuracy but also contributes to operational efficiency by reducing energy consumption and simplifying maintenance processes. Designed for eco-friendly performance, the GSort R minimizes environmental impact by eliminating the use of water in the separation process, ensuring sustainable and resource-efficient recycling operations.

functionality

How the GSort R Works: Efficient Density Separation

The GSort R operates on an innovative principle of density separation, enabling precise separation of different materials. It uses a combination of an inclined platform and a controlled airflow to sort materials based on their density. This method is characterized by its efficiency and adaptability, making it ideal for various recycling applications.

Separation Mechanism: Upward Airflow and Vibration in Harmony

The separation process relies on the interplay of airflow and mechanical vibration, ensuring a precise separation that can be optimally adjusted to material properties.

Lighter materials are lifted off the deck by the directed airflow and slide down due to the platform’s incline.

Heavier materials remain on the platform and move upward through vibration.

Flexibility Through Customization

The GSort R offers extensive adjustment options to meet diverse recycling requirements. This flexibility makes it a universal tool for numerous recycling processes.

Airflow: The intensity of the airflow can be precisely regulated to optimize separation performance.

Incline Angle: Adjusting the platform inclination allows for more efficient sorting of materials.

Vibration: Both the strength and frequency of the vibration can be varied to ensure even more accurate separation.

technical data

Optimized for Lightweight to Medium Recycling Applications

The GSort R is specifically designed for lightweight to medium recycling applications and provides an ideal solution for a variety of materials that need to be separated efficiently and resource-consciously. Its adaptable technology is perfectly tailored to the requirements of modern recycling processes.

Precise Process Speed for Optimal Results

With a processing speed of less than 4 m/s, the GSort R ensures gentle yet effective material separation. This speed is carefully chosen to achieve the optimal balance between energy efficiency and separation performance.

Suitable for Materials with Low to Medium Density

The GSort R is designed to separate materials with a density of less than 1.7 t/m³. This feature makes it particularly effective for sorting lightweight to medium-weight recycling materials commonly found in waste management.

Versatility in Particle Size

Capable of handling particle sizes ranging from 0.5 mm to 80 mm, the GSort R offers exceptional versatility. Whether dealing with finely shredded particles or larger material pieces, the system works reliably and delivers precise results.

Ideal for Glass, Plastics, and Textiles

The GSort R excels in separating recyclable materials such as glass, plastics, and textiles. Its precise density separation improves the quality of recovered raw materials and simplifies further processing.

Environmentally Friendly and Energy-Efficient

In addition to its high performance, the GSort R features low energy consumption and an innovative air filtration system. This reduces emissions and ensures clean exhaust air, offering both ecological and economic benefits. Its eco-friendly operation makes the GSort R a forward-thinking solution for sustainable recycling.

options

The GSort R is available in three models with table widths of 50 cm (R50), 100 cm (R100), and 150 cm (R150), tailored to different material volumes and recycling needs. The R50 stands out with its compact design for small-scale applications, the R100 is the versatile middle option for medium projects, and the R150 provides maximum capacity for large recycling facilities. For the R50 and R100 models, basic versions are also available, offering a cost-effective solution with the essential features of the GSort R series.

GSort R50: Table width of 50 cm

GSort R100: Table width of 100 cm

GSort R150: Table width of 150 cm

Available in basic versions for the R50 and R100 models

Application Areas

The GSORT R was specially developed for the precise separation and processing of a wide range of materials. Whether in metal and raw material processing, recycling or waste management – this high-performance sorting system ensures efficient separation and recycling of valuable materials. From fine manganese ore, glass and rubber to organic waste and RDF, the GSORT R offers reliable solutions for a wide range of applications. Thanks to state-of-the-art technology, it ensures optimized material processing and helps to conserve resources and increase the efficiency of industrial processes.

Suitable for precise separation of fine manganese ore during processing.

Effective for the separation and recycling of rubber materials.

Optimized for sorting and cleaning cullet.

Supports the separation of organic matter in compost.

Perfect for processing organic waste materials.

Enables efficient separation of refuse-derived fuel (RDF).

Specializes in sorting coal particles.

Ideal for the preparation and recycling of textiles.

Ensures precise separation of vermiculite minerals.

Designed for clean separation of PET films for recycling.

For Every Recycling Requirement

The GSort R offers a wide range of models designed to meet different material volumes and recycling demands. With three table widths – 50 cm, 100 cm, and 150 cm – the product line provides tailored solutions for recycling facilities of all sizes.

The Compact Option

The GSort R50, featuring a table width of 50 cm, is the compact solution for smaller recycling applications. It is ideal for handling lower material volumes or operating in confined spaces while maintaining the same precision and efficiency as its larger counterparts.

Versatile Mid-Range Model

With a table width of 100 cm, the GSort R100 is the perfect choice for medium-scale recycling tasks. This model combines flexibility with increased processing capacity, making it well-suited for a wide range of recycling materials and applications.

Maximum Capacity

For large-scale recycling projects, the GSort R150, with a table width of 150 cm, delivers maximum capacity and efficiency. Designed for facilities handling high material volumes, this model ensures top-tier precision and performance.

Base Versions

Base versions are available for the R50 and R100 models. These variants provide the essential features of the GSort R series and offer a cost-efficient solution for recycling projects that do not require an extended feature set. With the same reliability and quality, the base versions are ideal for entry-level density separation tasks.

Key Advantages

The GSort R offers an outstanding combination of flexibility, energy efficiency, and sustainability for demanding sorting processes. Designed to adapt to various material properties and particle sizes, it ensures precise material separation and maximum purity – ideal for lightweight to medium-weight materials.

High Flexibility

The GSort R easily adapts to changing material properties and varying particle sizes.

Energy-Efficient

Reduced power consumption per ton of processed materials thanks to an optimized air distribution system.

Easy Maintenance

Improved accessibility to maintenance components reduces downtime and lowers maintenance costs.

Optimized Separation

Ensures high purity when separating lightweight to medium-weight materials such as plastics and glass.

Environmentally Friendly

The dry separation technique saves water, significantly reducing the environmental impact of recycling processes.

Test Your Material with Our Machines

At our MOGENSEN Test Center, experience firsthand how our proven GSort R processes your material with maximum precision and efficiency. Rely on state-of-the-art technology and trusted results. Contact our sales team to schedule an appointment and test your material under real conditions. We look forward to supporting you!

Get in touch with us

Reach out to us quickly and directly by using the contact form. We will respond as soon as possible!