GSort M

The GSort M by MOGENSEN is the perfect solution for demanding density separation tasks in the mining industry, specifically tailored to meet the requirements of mineral and ore processing.

Equipped with cutting-edge technology and high adaptability, the GSort M ensures efficient operations even under the harshest mining conditions. This machine is designed to handle heavy materials such as ores, minerals, and other dense substances, ensuring precise and reliable separation of materials with different densities. Its robust design, combined with ease of operation and maintenance, makes the GSort M ideal for long-term use in mining applications where durability and high performance are crucial. Additionally, the GSort M contributes to cost savings by reducing water and energy consumption, making it an environmentally friendly choice for industrial mining processes that demand both precision and sustainability.

functionality

How the GSort M Works

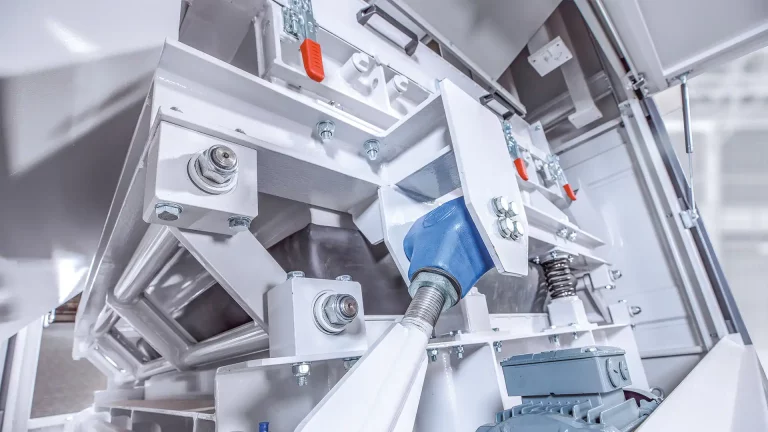

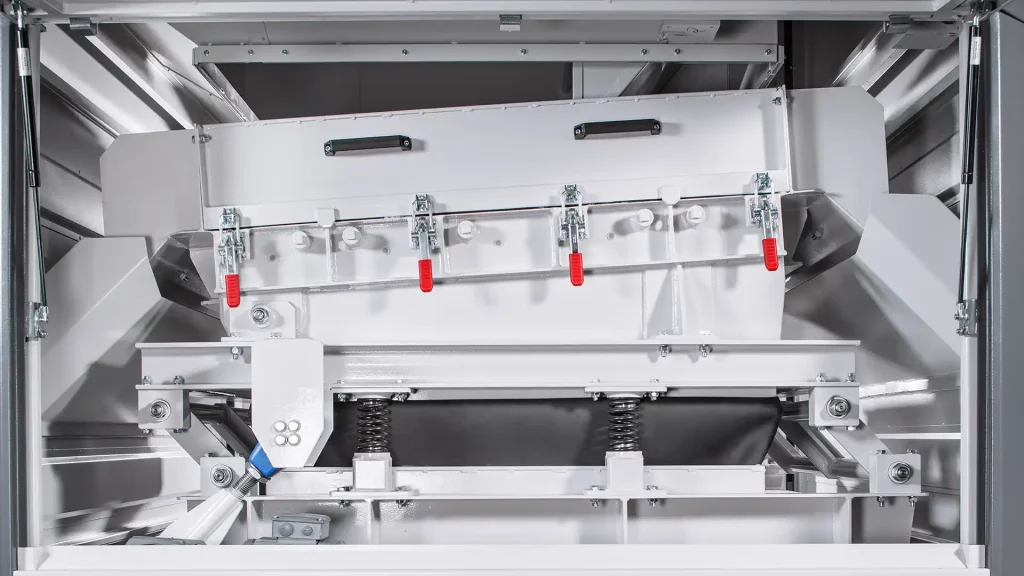

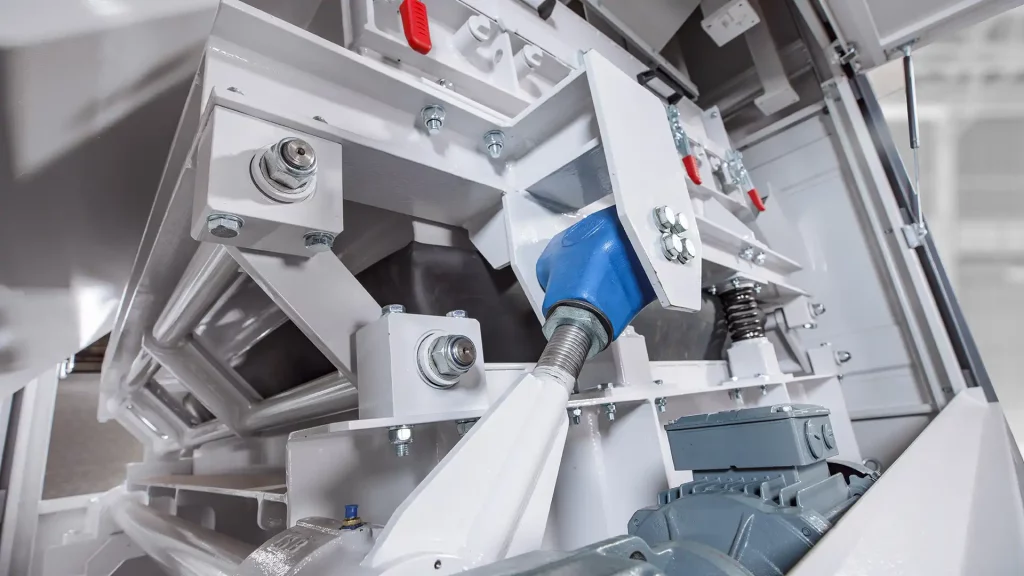

The GSort M separates materials based on density using an inclined, vibrating platform and a controlled airflow. The inclined deck and upward airflow allow lighter particles to slide downward while heavier materials remain on the surface and are transported upward. The system allows precise control of air speed, deck inclination, and vibration to customize performance for various mining applications. A built-in air filtration system ensures efficient dust collection and environmentally friendly operation.

Efficient Density Separation Through Innovative Technology

At the heart of the GSort M’s separation process is its inclined, vibrating platform that works in conjunction with directed airflow. Light particles are guided downward, while heavier materials remain on the deck and are moved in the opposite direction. This innovative density separation method allows for precise exploitation of even fine density differences, making it highly advantageous for processing minerals and ores.

Adaptability for Versatile Mining Requirements

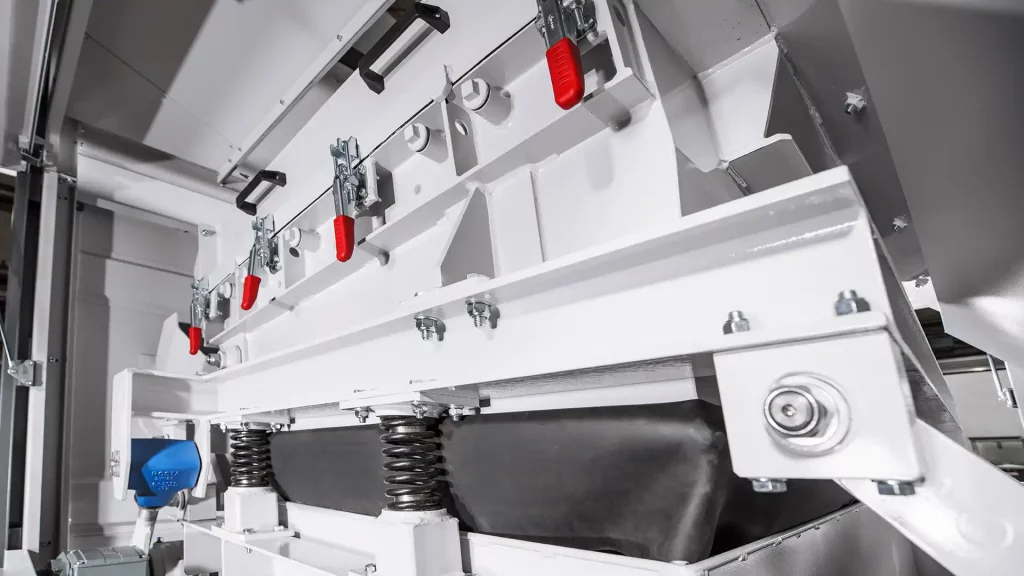

One of the GSort M’s greatest strengths is its precise control of key parameters: air speed, deck inclination, and vibration. These factors can be adjusted individually, enabling the GSort M to adapt to various mining demands. Whether separating raw materials with differing densities or sorting ore mixtures, the machine offers high adaptability to process conditions, delivering optimal results. Additionally, the GSort M features a robust, specially designed air filtration system that ensures efficient dust collection. This system not only enhances workplace safety but also makes operations more environmentally friendly.

Modularity and Easy Integration

The modular construction of the GSort M enables easy integration into existing facilities. Its compact design saves space and reduces installation time, while straightforward maintenance with quick access to key components minimizes downtime. The GSort M can also be equipped with additional sensors and control systems for automatic parameter adjustments in response to changing material properties, improving process efficiency and ensuring consistent separation performance regardless of raw material quality fluctuations.

Sustainability and Efficiency for the Future of Mining

By combining advanced technology, high adaptability, and an efficient air filtration system, the GSort M is an excellent solution for companies focusing on sustainability and efficiency. The machine not only optimizes material separation but also contributes to reducing emissions and operational costs, making it a future-proof investment for the mining industry.

technical data

Specially Designed for Mining Applications

The GSort M is specifically engineered for the challenges of mining, delivering exceptional performance even in demanding conditions. Its robust construction and advanced technology make it a reliable solution for various mining operations.

High Process Speed for Optimal Separation

With a processing speed exceeding 3 m/s, the GSort M ensures effective material separation. This high speed enables the machine to exploit fine density differences and achieve precise separation results.

Processing Heavy Minerals and Large Particles

The GSort M is designed to process materials with a density exceeding 1.3 t/m³ and handle particle sizes of up to 80 mm, depending on material properties. This makes it particularly suitable for processing heavy minerals and ores.

Ideal for Robust and Demanding Applications

Its durable construction and high-performance separation technology make the GSort M ideal for extremely robust applications. It offers high operational reliability and longevity, making it the perfect choice for mining operations that require efficiency and dependability.

Key Specifications

- Process Speed: Over 3 m/s

- Density: > 1.3 t/m³

- Particle Site: Up to 80 mm, depending on the material

- Optimized Performance for Heavy Minerals and Ores

- Suitable for Extremely Robust Applications

options

The GSort M is available in three models with varying widths to accommodate different material volumes and mining requirements. Additionally, up to four units can be operated in parallel for higher capacity, offering flexibility in system configuration and optimal workspace utilization.

G06: Table width of 50 cm

G13: Table width of 100 cm

G19: Table width of 150 cm

Expandable to parallel operation with up to four units

Applications

The GSort M is versatile and optimizes the separation of different materials through precise density separation technology. Whether in mining, recycling or heavy industry – it enables efficient processing and ensures the sustainable use of valuable raw materials.

Optimizes the separation of coal particles with precise density sorting, improving mining efficiency.

Effectively separates magnesite, making it ideal for industrial mining applications.

Provides exceptional performance in processing barite, a critical raw material in heavy industry.

Processes celestine efficiently with reliable density separation technology.

Designed for precise hematite separation to maximize ore processing yields.

Ensures highly efficient manganese ore separation for optimal resource recovery.

Ideal for density separation of ferro-manganese, delivering high-quality results for the metal industry.

Offers an adaptable solution for attapulgite processing, even under challenging conditions.

Supports aluminum recycling by efficiently separating dense materials and promoting sustainability.

Optimizes the separation of crushed cables to recover valuable raw materials.

Precisely separates crushed demolition waste, simplifying the reuse of construction materials.

A Variety of Models

The G-Series provides powerful solutions with various table widths tailored to different material volumes and mining needs. Whether for compact applications or large-scale projects, the G-Series offers optimal adaptability to individual requirements with its G06, G13, and G19 models.

The Compact Option

Versatile Mid-Range Model

The G13, featuring a table width of 100 cm, strikes the ideal balance between capacity and flexibility. It is suitable for a wide range of mining applications and is particularly effective for medium material volumes.

Maximum Performance

Scalability for Enhanced Efficiency

Key Advantages

The GSort M offers an innovative solution for efficient and eco-friendly separation of heavy minerals and ores. With maximum sorting accuracy, low operating costs, and exceptional flexibility, its robust and durable design makes it ideal for continuous operation in demanding environments.

Longevity

Engineered for continuous operation in demanding environments.

Increased Efficiency

Ensures higher sorting accuracy for heavy minerals and ores.

Operational Efficiency

Robust design results in lower energy consumption and maintenance costs.

Environmentally Friendly

Designed to save water and significantly reduce energy consumption.

Maximum Flexibility

Airflow and deck inclination can be customized for various material densities.

Test Your Material with Our Machines

At our MOGENSEN Test Center, you can experience firsthand how our proven GSort M processes your material with the highest precision and efficiency. Rely on cutting-edge technology and reliable results. Contact our sales team to schedule an appointment and test your material under real conditions. We look forward to assisting you!

Get in touch with us

Reach out to us quickly and directly by using the contact form. We will respond as soon as possible!