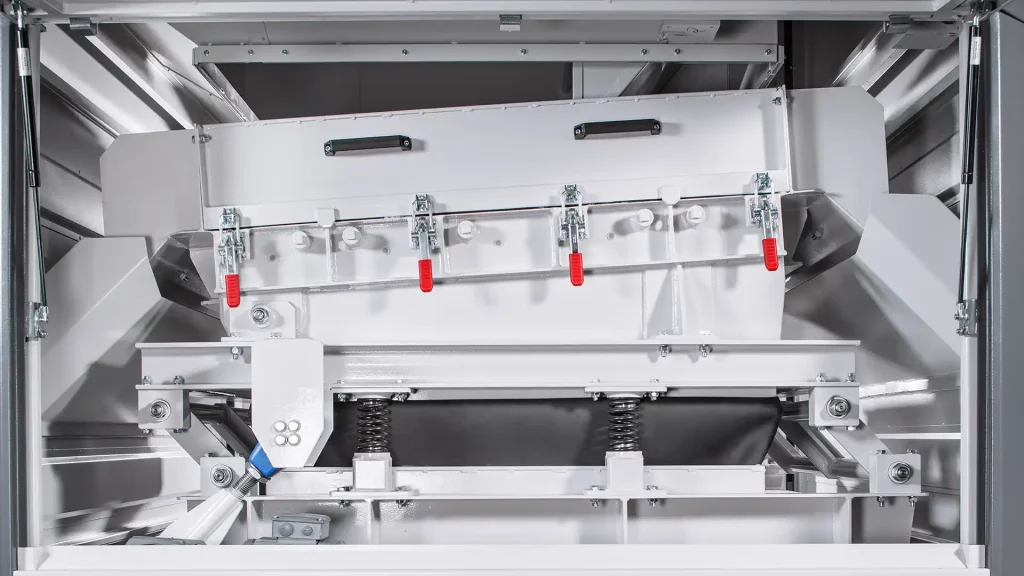

Precise Density Separation for Industry and Recycling

The GSort product line from MOGENSEN offers cutting-edge solutions for demanding density separation tasks. With innovative technology and a robust design, these machines are specifically tailored to meet the requirements of industry, mining, and recycling processes. They ensure efficient and sustainable material separation, helping businesses optimize their production processes and operate more environmentally friendly.

GSort R – Density Separation in the Recycling Sector

Maximum Precision for Sustainable Recycling Processes

The GSort R is specifically designed for the recycling industry, providing efficient separation of light to medium-weight materials such as plastics, glass, textiles, and other recyclables. With its precision-engineered technology, it ensures accurate sorting and maximum flexibility.

- Ideal for circular economy applications

- High sorting accuracy across various materials

- Energy-efficient and low-maintenance design

- No water usage in the separation process for eco-friendly performance

- Reduces operating costs through low energy consumption

- Sustainable and resource-efficient operation

The GSort R helps recycling companies optimize their processes and ensures highly efficient material separation. It not only lowers energy consumption but also ensures that valuable materials are available for reuse thanks to its precise sorting technology. This makes it a key player in the modern circular economy, supporting companies in implementing sustainable production strategies.

GSort M – Density Separation for the Mining Industry

Maximum Efficiency Under the Toughest Conditions

The GSort M is specifically developed for the mining industry and the processing of heavy materials such as ores and minerals. With high adaptability and state-of-the-art technology, it ensures efficient and precise separation of materials with varying densities. Designed for operation in extreme environments, it stands out with its robust construction and long-lasting durability.

- Heavy-duty design for extreme conditions

- High separation precision for dense materials

- Durable and easy to maintain

- Reduced water and energy consumption for greater sustainability

- Ideal for demanding mining applications

- High efficiency even with large material volumes

By utilizing the GSort M, businesses can reduce operating costs and use resources efficiently. With its high sorting accuracy, it helps minimize raw material loss and ensures environmentally friendly processing. Mining companies benefit from its reliable performance, enabling long-term economic efficiency.

Key Differences at a Glance

With MOGENSEN’s GSort machines, you are investing in cutting-edge technology for efficient and sustainable material separation — whether in mining or recycling. Businesses benefit from innovative solutions that offer both economic and environmental advantages. Thanks to their high adaptability and advanced technology, these machines enable long-term optimization of operational processes.

Mining

Recycling

Ores, minerals, dense substances

Plastics, glass, textiles

Very high (extreme conditions)

High (industrial recycling processes)

Reduced

No water required

Energy-efficient

Resource-efficient

High efficiency for heavy materials

High precision for recyclable materials

Mining

Recycling

Ores, minerals, dense substances

Plastics, glass, textiles

Very high (extreme conditions)

High (industrial recycling processes)

Reduced

No water required

Energy-efficient

Resource-efficient

High efficiency for heavy materials

High precision for recyclable materials

Contact Us to Find the Right Solution for Your Needs!

Precision & Efficiency

The GSort machines not only provide exceptional precision in material separation but also help optimize resource usage and reduce production costs. Their robust design ensures reliable operation even under demanding conditions. Businesses across various industries can increase efficiency, reduce waste, and contribute to sustainability.

Easy Maintenance & Cost-Effectiveness

Additionally, the easy maintenance and user-friendly operation of the machines allow for seamless integration into existing production and recycling processes. Equipped with advanced sensor technology and precise control systems, they deliver consistently high performance while minimizing material losses. This leads to improved cost-effectiveness and helps businesses achieve their environmental goals.