Company History Since 1947

Since 1947, MOGENSEN has showcased its expertise at locations in Germany, Sweden, and Spain. Building on over 18,000 test runs, MOGENSEN has already convinced more than 20,000 customers worldwide with solutions related to screening, conveying, distributing, separating, and washing. These innovative solutions are used in various industries such as mining and minerals, chemicals, foundries, food, recycling, and animal feed.

As a globally recognized technology leader in the field of precise screening and sorting solutions, we have made a name for ourselves both nationally and internationally. With over 10,000 screens in operation today, we set global standards in bulk material classification. Our machines are designed for peak performance and provide customized solutions for the most complex requirements of our customers. The company’s four main products – the MSizer Family (Compact, Extend, Giant), GSorts (GSort M and GSort R), conveyors, and sand washing plants – set standards in performance, precision, and sustainability.

Our goal is to always deliver the best results through continuous development and the use of the latest technologies. We are committed to quality and reliability and are proud to be a trusted partner to companies worldwide.

Our name is our promise: precision, innovation, and highest performance – that’s what MOGENSEN has stood for over seven decades.

History & Development

Our journey began with the clear goal of improving efficiency in screening technology. Over the years, we have continuously expanded our portfolio and developed innovative solutions like the MSizer, a highly precise screening machine.

A significant milestone in our company history was our integration into the JOEST group on January 1, 2024. Through this partnership, we can access additional resources and technological innovations that help us serve our global customers even better.

MOGENSEN focuses on the development of groundbreaking technologies. We understand the needs of our customers and offer not only innovative products but also customized solutions for a variety of applications.

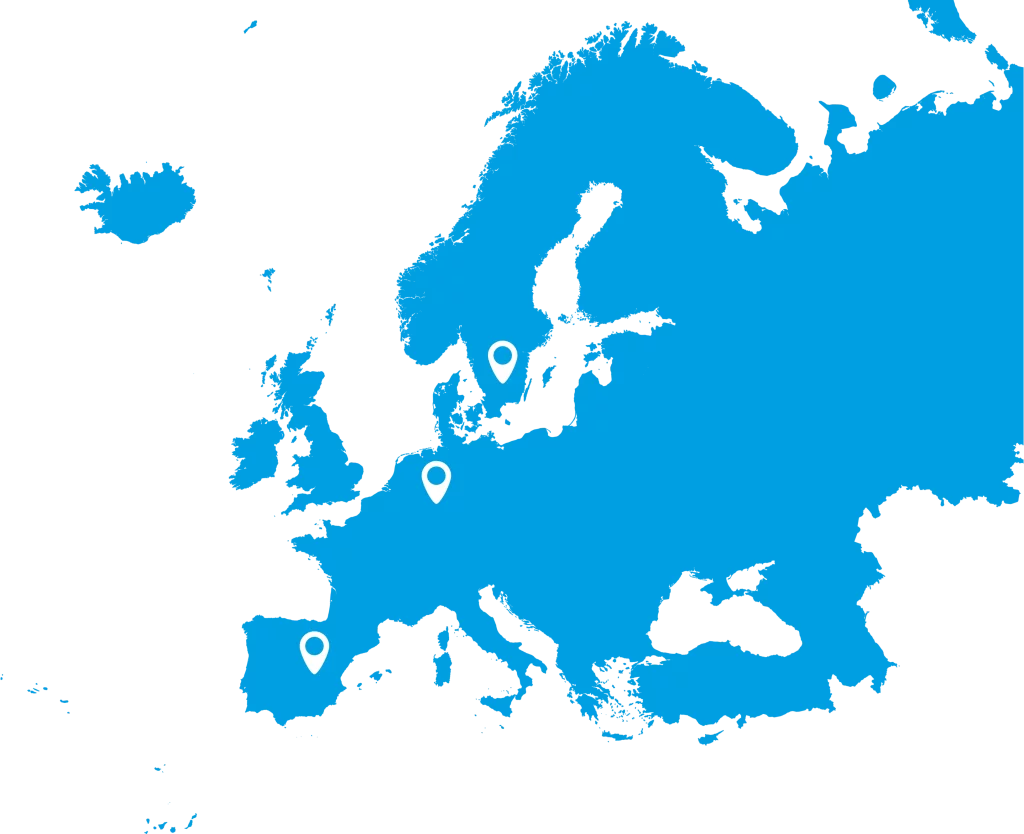

Global Presence

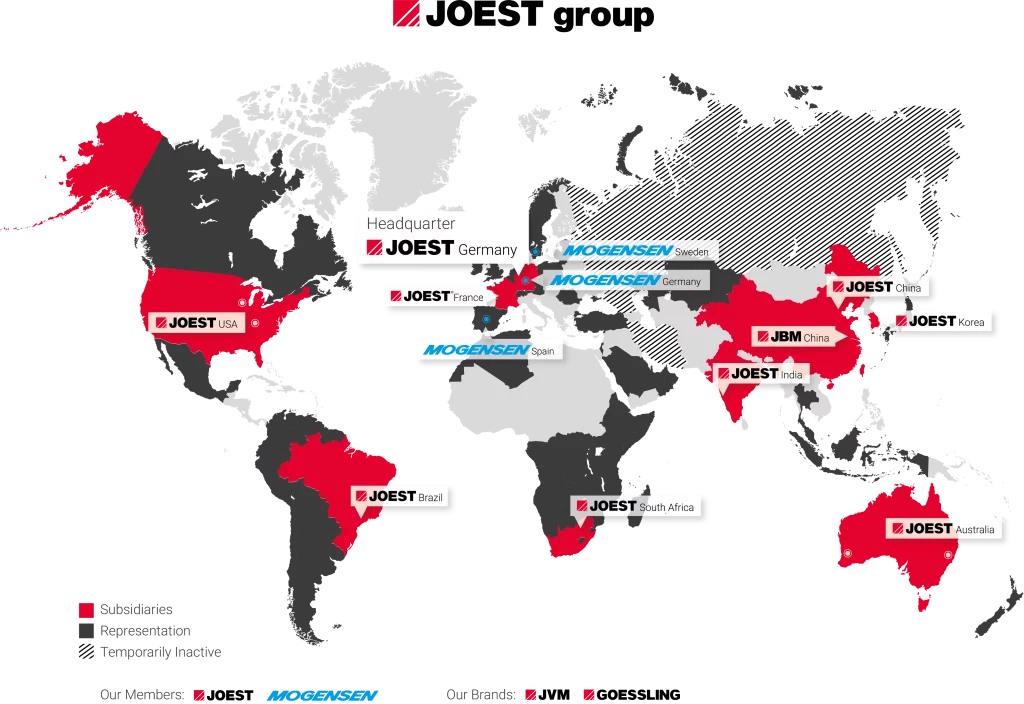

We have locations in Wedel, Germany, Madrid, Spain and Hjo, Sweden. This allows us to operate close to our customers and respond to their specific needs individually. Furthermore, the support of the globally represented JOEST group, with its 12 subsidiaries, ensures that a local expert team is always available, all around the world. Thanks to this international presence, we are able to efficiently deliver tailored solutions worldwide.

Our Locations

Each of our locations is optimally equipped to provide you with the support of our expert team directly on-site. Here you’ll find detailed addresses and contact information, so you can reach us quickly and easily—whether for inquiries, consultations, or personalized assistance. We look forward to helping you!

Our Product Portfolio

Our Screening Technology

The MSizer Family offers powerful classification machines based on the innovative Sizer principle, known for high efficiency, flexibility, and process stability. With models like the compact MSizer Compact, versatile MSizer Extend, and powerful MSizer Giant, they cover a wide range of applications and increase throughput and productivity.

The MOGENSEN Sizer® principle enables fast separation processes, reduces wear and blockages, and offers high screening accuracy. With up to six screen decks and seven fractions, these machines save space, energy, and maintenance costs – a modern solution for demanding screening tasks.

Our GSort Technology

The GSort product line from MOGENSEN offers efficient and precise density separation solutions for various industries:

GSort M: Specifically developed for mining, this machine is ideal for heavy materials like ores and minerals. It is known for its robust design, low operating costs, and sustainable use of water and energy.

GSort R: Optimized for the recycling industry, this machine reliably separates materials like plastics, glass, or textiles in an eco-friendly manner. The water-free operation supports a sustainable circular economy and enhances the efficiency of modern recycling processes.

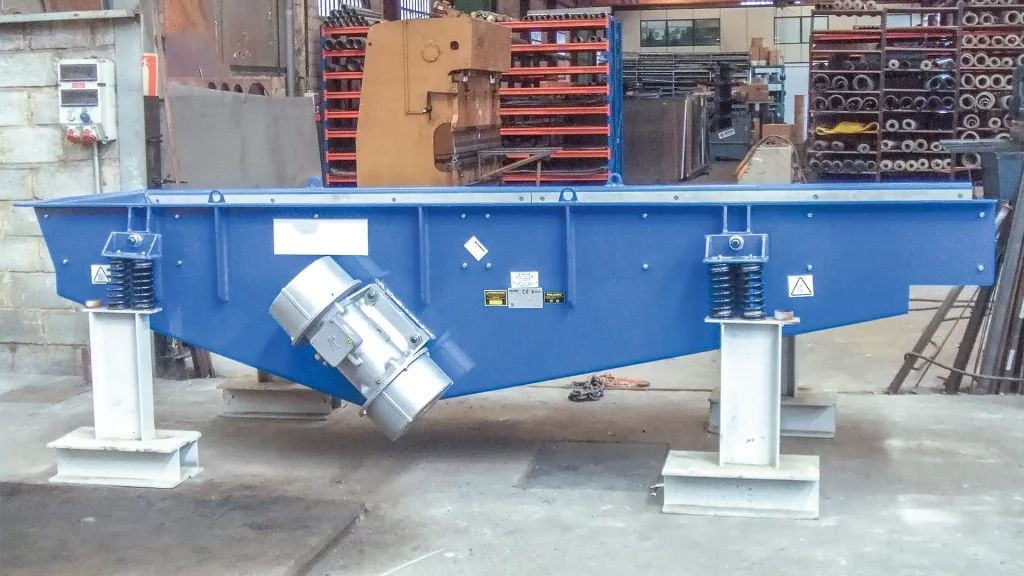

Our Feeding Technology

MOGENSEN’s conveyors and distributor chutes are specifically designed to enhance the efficiency of screening and sorting processes. They ensure precise and consistent material feeding, contributing to optimized screening quality and throughput. Thanks to custom adjustments, such as tailored inlets and outlets and special wear-resistant materials, these chutes are highly flexible and durable. Their robust design and maintenance-friendly construction make them a reliable solution for demanding industrial applications. Additionally, the powerful drives ensure smooth operation, even under difficult conditions.

Our Sand Washing Plants

MOGENSEN sand washing plants ensure the production of high-quality sand that meets the highest industrial standards. They optimize grain size, fineness modulus, cleanliness, and spreadability while effectively removing unwanted substances like organic materials, chlorides, and sulfates.

These plants have versatile applications, such as concrete production, frac sand, foundry sand, and the processing of minerals like bentonite slurries. They not only ensure consistently high sand quality but also improve the efficiency and sustainability of production through optimized material usage. This makes them indispensable for demanding industrial processes.

Applications

Thanks to our versatile technologies, MOGENSEN offers tailor-made solutions for a wide range of industries: from precise and hygienic screening and classification systems for food processing to reliable separation of recycling materials and accurate sieving of chemicals. In mining, our systems ensure efficient classification of raw materials like gravel and ore, while in foundries, they optimize the processing of molding sands. In the animal feed industry, they ensure consistent quality and optimal nutrient distribution. MOGENSEN stands for the highest precision, efficiency, and adaptability in every industry.

Mining & Minerals

MOGENSEN provides robust systems for the efficient processing of ores, minerals, and other raw materials under the toughest conditions.

Chemicals

MOGENSEN technology enables the precise and safe classification of chemical powders and granules for industrial applications.

Foundries

Our machines ensure reliable classification and processing of sand and other materials essential in the foundry industry.

Animal Feed

With our solutions, feed ingredients are efficiently classified and processed to ensure optimal quality and consistency.

Food

Our sieving and classification technology guarantees the highest hygiene and precision in food processing.

Recycling

MOGENSEN solutions enable precise material separation and promote efficient circular economy processes through resource-conserving methods.

MOGENSEN as part of the JOEST group

As a subsidiary of the JOEST group, MOGENSEN combines its expertise in screening and sorting technology with over 100 years of experience in vibration technology. Together, we offer tailored solutions for various industries – from mining and recycling to complex industrial processes.

Based in Dülmen, Germany, the JOEST group is a global leader in mechanical engineering, offering customized solutions for bulk material handling. With its roots in vibration technology, the company has continuously broadened its expertise over the years to include conveying, lifting, tipping, screening, sorting, separating and thermal processing. Today, JOEST stands for innovation, precision, and adaptability, serving a wide range of industries around the world.

MOGENSEN complements this portfolio with cutting-edge products like the MSizer Family, GSort solutions, and robust conveyors and distributor chutes. The synergy of the two companies results in efficient, sustainable, and customer-focused solutions that set global standards.

Get in touch with us

Reach out to us quickly and directly by using the contact form. We will respond as soon as possible!